WIRE AND CABLE MANAGEMENT

PRODUCT HIGHLIGHTS

Cable Assemblies and Power Whips

Cable assemblies and power whips are pre-assembled bundles of cables, wires, and connectors that are designed to connect power or data sources to different components or devices in industrial automation.

-

Cable assemblies can include different types of cables, such as power cables, control cables, or communication cables, depending on the application and system requirements.

-

Power whips are pre-assembled power cables that are used to connect power sources, such as electrical panels or generators, to industrial equipment or machines.

-

Cable assemblies and power whips can be customized to fit specific requirements, such as length, gauge, or connector type, to ensure optimal performance and compatibility.

-

Cable assemblies and power whips are typically tested for electrical performance and quality assurance before being shipped to customers.

-

Cable assemblies and power whips can significantly reduce installation time, minimize the risk of wiring errors, and ensure consistent and reliable power delivery to industrial automation systems.

Cable Bridges

Cable bridges, also known as cable ramps or cable protectors, are support systems that provide a safe and organized path for cables and wires in industrial settings.

-

Cable bridges can be made of different materials, such as steel, aluminum, or plastic, depending on the application, environment, and load requirements.

-

Cable bridges come in different sizes, shapes, and configurations to fit various cable management needs, such as straight sections, turns, intersections, or tees.

-

Cable bridges can be installed overhead, underfloor, or along walls, depending on the space availability and system design.

-

Cable bridges can significantly reduce cable installation time and costs, minimize cable damage and wear, and facilitate cable maintenance and repair.

-

Cable bridges also improve safety by preventing cable-related accidents, such as tripping, fire, or electric shock.

Cable Glands & Cord Grips

Cable glands and cord grips are devices used to secure and seal cables and wires passing through a panel or enclosure.

-

Cable glands and cord grips are available in various sizes and materials to accommodate different cable sizes and environmental conditions.

-

Cable glands and cord grips provide strain relief, preventing cables from being pulled out of the panel or enclosure, which can damage the cable or cause a safety hazard.

-

Cable glands and cord grips provide ingress protection, preventing dust, water, and other contaminants from entering the panel or enclosure through the cable entry point.

-

Cable glands and cord grips come in different types, such as dome, flex, or strain relief, depending on the application and cable type.

-

Cable glands and cord grips can be used in a wide range of industries, including manufacturing, automation, marine, oil and gas, and renewable energy.

Conduit & Cable Tray

Conduit and cable tray are used in a wide range of industries, including manufacturing, automation, and construction, to protect and organize cables and wires and ensure safety and reliability

-

A conduit is a tube or channel that protects cables and wires from damage and external elements, such as moisture, chemicals, and physical impact.

-

Conduit can be made of various materials, such as steel, PVC, or aluminum, and comes in different sizes and types, such as rigid, flexible, or liquid-tight.

-

A cable tray is a support system that allows cables and wires to be organized and routed in a safe and efficient manner.

-

Cable tray can be made of various materials, such as steel, aluminum, or fiberglass, and comes in different sizes and types, such as ladder, basket, or solid-bottom.

-

Conduit and cable trays can be installed in different ways, such as surface-mounted, embedded, or suspended, depending on the application and environment.

Electrical Raceway & Wire Duct

The electrical raceway is a protective channel or conduit that encloses wires and cables to prevent damage and exposure to hazardous conditions.

-

Wire duct is a type of raceway that provides a way to route and organize wires and cables in a compact and organized manner.

-

Electrical raceways and wire duct are made of various materials, such as PVC, metal, or fiberglass, and come in different sizes and configurations.

-

Electrical raceway and wire duct can be used in a wide range of applications, including industrial automation, control systems, and power distribution.

-

They are designed to meet specific standards for safety and performance, such as UL and NEC, and can be customized to fit specific needs.

-

Electrical raceway and wire duct can be installed in a variety of ways, such as surface-mounted, embedded, or suspended, depending on the application and environment.

Fiber Optic Cables

Fiber optic cables use thin strands of glass or plastic to transmit data and signals over long distances.

-

They are often used in manufacturing and automation systems because they can transmit signals faster and more reliably than traditional copper cables.

-

Fiber optic cables are immune to electromagnetic interference, making them ideal for use in areas with high levels of electrical noise.

-

They are also more resistant to damage from environmental factors like moisture, heat, and corrosion.

-

Fiber optic cables come in different types, including single-mode and multi-mode, and can be terminated with various connectors, such as SC, ST, and LC.

-

Installation of fiber optic cables can be more challenging than copper cables due to their fragility and sensitivity to bends and kinks.

-

However, with proper handling and installation techniques, fiber optic cables can provide high-speed and reliable data transmission in manufacturing and automation systems.

M12 Cables

M12 cables are circular, threaded connectors commonly used in manufacturing and automation applications for sensors, actuators, and other devices.

-

They come in different versions, including 4-pin, 5-pin, and 8-pin, and can support both data and power transmission.

-

M12 cables are designed to withstand harsh industrial environments, with features such as IP67 or IP68 ratings for protection against dust, moisture, and vibration.

-

They are easy to install and can be quickly and securely connected to devices without the need for special tools or equipment.

-

M12 cables are also resistant to electromagnetic interference, making them suitable for use in areas with high levels of electrical noise.

-

With their small size and high reliability, M12 cables are a popular choice for industrial automation systems, particularly those involving sensors and other control devices.

Network Cables (Structured Cabling)

Network cables, also known as structured cabling, are used to establish a reliable and efficient network infrastructure in manufacturing and automation settings.

-

They consist of copper or fiber optic wires that are bundled together in a specific arrangement to minimize signal interference and maximize data transmission speed.

-

Structured cabling is a standardized approach to network cable installation that ensures compatibility and scalability with different devices and applications.

-

It includes various components such as patch panels, switches, routers, and connectors that are designed to work together seamlessly and optimize network performance.

-

Some common types of network cables used in manufacturing and automation include Cat5e, Cat6, and fiber optic cables.

-

Proper installation and maintenance of network cables are essential for ensuring the stability and security of the network, as well as preventing costly downtime and data loss.

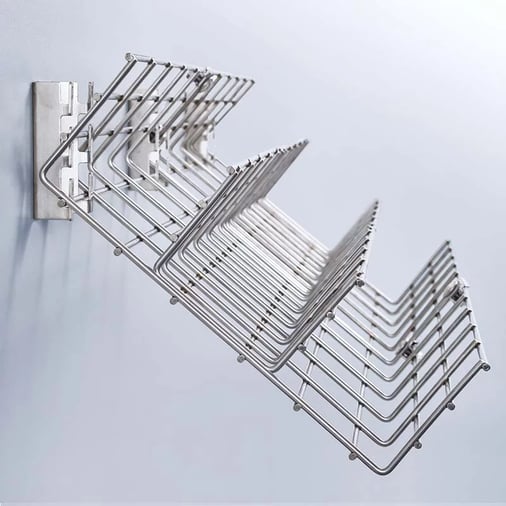

Wire Tray (Basket Tray)

Wire tray, also known as basket tray or cable tray, is a type of wire management system used in manufacturing and automation environments.

-

It consists of a series of interconnected metal wires or rods, forming a basket-like structure to hold and organize cables and wires.

-

Wire trays can be used for both power and data cables and can support heavy loads, making them ideal for industrial applications.

-

They come in various sizes, materials, and shapes, including straight sections, bends, and tees, to fit different installation requirements.

-

Wire trays offer several advantages, including easy installation, low maintenance, and improved airflow around cables to prevent overheating.

-

Wire trays can be grounded to reduce the risk of electrical interference and meet safety regulations.

-

Some wire trays are designed to be corrosion-resistant, making them suitable for harsh environments.

-

Wire trays can also be combined with other wire management systems such as cable ties, conduit, and raceways to create a comprehensive wire management solution.

©2025 DMCS® - All rights reserved. Privacy